Introduction

Supply chain outsourcing is becoming a game-changer for companies looking to meet 2025’s rising customer expectations. In the age of consumerization, where end-users expect on-demand, easy-to-follow, and always-in-control order experiences, the expectation is that companies can no longer depend on in-house resources to handle complicated logistics. That’s where contracted supply chain management can step in to streamline the systems and enhance productivity.

By partnering with third-party supply chain service providers, retailers have the opportunity to stack the deck at every stage of the fulfillment cycle, from the front-end and inventory management to processing and returns. Each of these solution providers offers fresh enhancements of technology, strategy, and logistics to optimize delivery performance, reduce errors, and improve the customer experience.

Relying on an outsourcing model has also become a common way for more organizations to predict demand and reduce stockouts and to react in real-time to market conditions. Together with process improvement and supply chain outsourcing, these services can reduce latencies and increase flexibility.

Whether you’re a high-growth start-up or a growing large corporation looking for scale, systems, and process optimization, the decision to outsource and transform your supply chain and logistics performance is a better way to productivity and to growth. The result? A speedier, more agile, and customer-centric business model that is prepared for the future.

What is Supply Chain Outsourcing?

When you outsource the supply chain, you’re turning over all or part of your supply chain operations to an outside expert. These are tasks such as logistics, warehousing, procurement, inventory management, and order management. This enables a company to optimize processes, reduce costs, and get to market quicker by consuming the capabilities and services of third parties.

Outsourcing is more than just offloading work; it’s growing your stable of outside skills. To remain agile and competitive, enterprises are turning to smart alternatives, according as outsourcing supply chain management to third-party operations, and beyond.

There are a few flavors of supply chain outsourcing that do offer a meaningful benefit:

1. Maintenance of Open Supply Chain:

It is a function that enables organizations to maintain their supply chain operations (e.g., logistic coordination, inventory management, procurement, etc.), hived off to specialists to ensure the highest levels of accuracy and consistency.

2. Third-Party Supply Chain Services:

Offers connections to third-party networks and fulfillment centers that can reduce shipping time and cost and increase market reach.

3. Supply Chain Optimization Outsourcing:

Focuses on the general effectiveness of the process, minimizes waste accumulation, and fine-tunes the operation in order to acquire higher output and monetary gains.

4. Supply Chain Performance Improvement Outsourcing:

Manages and continues to improve the supply chain performance through the use of KPIs to increase speed, reliability, and customer satisfaction.

5. Outsourced Vendor and Supplier Management:

Centrally manages relationships and communication between other vendors and the company, and also creates visibility into that external network that can lead to predictable procurements and shorter delays.

6. Predictive Supply Chain Outsourcing:

An approach that leverages AI and data analytics to predict demand, manage inventory, and prevent disruption before it takes place.

7. Process Improvement Outsourcing Model:

This type of outsourcing targets the bottlenecks and areas of friction in the supply chain and procures improvement methodologies to enhance effectiveness.

In conclusion, this strategy is not an operational decision at all; it is a strategic shift to more intelligent, quicker, and more agile supply-chain ecosystems.

Common Functions in Supply Chain That Can be Outsourced

You don’t need to outsource everything from your jump. For many companies, outsourcing to key external areas of expertise is just the starting point. Through their use of third-party supply chain services, organisations are able to save money that can be reinvested into the business, reducing the amount of time it will take to grow and to reinvest resources to focus on customer satisfaction.

1. Order Fulfillment

Using dedicated service providers accelerates order picking, packing, and shipping. They have automated processes and large-scale infrastructure to process high volumes of transactions accurately. By using supply chain outsourcing, companies can decrease the time products spend in transit, increase the precision of orders, and ultimately increase customer satisfaction. It’s a potent way to compete in markets where speed is everything.

2. Inventory Management

A continuous and correct inventory is crucial for a good working process, and the outsourced supply chain management to be the one that uses real-time tracking, a long-term forecasting tool, or automatic stock replenishment. Such services prevent overstocking, stockouts, and operational delays. Through collaboration with accurately predicted supply chain outsourcing providers, companies can predict changes in demand and construct optimal inventory piles.

3. Warehousing & Distribution

Warehouse infrastructure is expensive to build and maintain. Rather, businesses can employ 3rd party suppliers with strategically placed plants who can ship faster and with minimal exposure. This model also facilitates outsourced management for supply chain performance improvement by reducing lead time and then to improve service reliability.

4. Coordination of Vendors and Suppliers

The coordination between the manufacturer and the distributor (i.e., supply chain coordination) can be seen from two perspectives: the pure supply chain coordination and the assistance and support of the distributor by the manufacturer. Businesses will also expedite the process of contacting other businesses with whom they are subletting by 3rd party vendors and suppliers. This leads to higher product availability, helps improve the delivery reliability, and reduces suppliers’ delays.

5. Returns Handling

Reverse logistics can take a toll on internal teams. By outsourcing this, progress track returns can be handled efficiently, allowing for a seamless customer experience. With Masterbond Returns, returns management is the part of a greater means to an end process improvement supply chain outsourcing, errors are minimized, restock time is minimized, and refund residuals are reduced.

6. Transportation Management

Carriers, routes, and delivery tracking are too much for internal logistics. By outsourcing supply chain optimization to us, businesses can streamline routes, minimize shipping-related costs, and increase delivery speed. Leveraging data and performance, and automation, these partners can deliver faster and more consistent transportation results.

Through selective outsourcing of these supply chain functions, firms are able to reset their operating model for agility, reduce organizational complexity, and open opportunities to scale that would simply not be available while also delivering topline customer fulfillment.

Advantages of Outsourced Supply Chain Management

1. Quicker Fulfillment and Delivery

3PLs have also positioned distribution networks and fulfillment centers in proximity to customer clusters. That geographical position means quicker shipping and faster response to whatever the market is changing to.

2. Improved Inventory Accuracy

In outsourcing for supply chain performance enhancement, businesses use systems and automations to monitor and manage inventory levels. Result: Fewer mistakes, less waste, and more production efficiency.

3. Technology-Driven Operations

No need to even build the supply chain tech, since working with third-party supply chain providers will grant you access to the best tech in the industry (real-time tracking, automated order management, AI demand forecasting, etc.)

4. Scalable Solutions

Outsourced services are capable of scaling up rapidly during peak seasons or periods of growth, with no capital investment in building new warehouses or hiring extra staff.

5. Reduced Costs

How does outsourced supply chain management save companies money? By turning fixed costs into variable costs, companies can lower their labor costs and take advantage of the operating efficiencies that third-party providers bring to the table.

How is Predictive Analytics Changing the Face of Outsourced Supply Chains

Among the most significant transformations of supply chain outsourcing is the use of predictive analytics. Traditional models see companies frequently responding to disruptions such as stockouts or delays in shipping after they’ve already occurred and begun to disrupt operations. Yet today, through proactive supply chain outsourcing, companies can simply know in advance and do something about problems before they occur. These nuggets drive down risk, speed up delivery, and increase customer satisfaction.

Here’s how prescriptive capabilities are transforming outsourced supply chain management:

1. Smarter Forecasting

With predictive analytics, companies can analyze historical performance, seasonal trends, and recent market changes to predict demand with an incredibly high level of precision. That means you optimize and stock, just in time, never a day earlier than you have to, minimizing the costs of stock holding, and maximizing the amount of stock you have without losing out on sales. AI-based supply chain optimization outsourcing makes sure that your stock is in tune with customer necessity even before they’re spoken. This proactive mindset results in more consistent delivery of orders and higher customer satisfaction.

2. Real-Time Adjustments

Internet-based third-party supply chain services have advanced systems that permit real-time changes to logistics plans. These real-time decisions involve time and money and cut into margins and profits, whether the need is to divert a shipment because of weather-related delays or to reallocate stock to adjust for demand by region.

Changes the way your supply chain runs. Supply chain process improvement outsourcing emphasizes a dynamic plan that is responsive to market changes and supply chain disruptions as they occur to reduce delays.

3. Supplier Risk Management

Predictive models can analyze supplier performance and identify risks, such as those related to delivery inconsistency or non-compliance. The solution also allows companies to ‘get ahead of’ supplier-side risk through increased visibility and early remediation. This minimises delays, guarantees continuity and enhances long-term supply chain resilience, something which is particularly significant in the ever-fluctuating global markets.

4. Warehouse Optimization

Warehouse operations also benefit from predictive analytics as bottlenecks can be identified, picking routes optimised, and layout efficiencies enhanced. This both increases the speed of filling orders and decreases errors in fulfillment. By incorporating warehouse outsourcing, it would ensure less waste in operations and decreased cycle times for companies. The outcome is a streamlined, less expensive supply chain that can handle high-volume growth without losing precision.

When an organization integrates predictive analytics with outsourced supply chain management, it provides businesses the agility and intelligence required to compete in today’s customer-centric, fast-paced global economy. It changes fulfillment from a reactive to a proactive function, enabling better service at a lower cost.

How Supply Chain Outsourcing Enhances the Customer Experience?

Experience of the magnitude of over 500,000 orders and 100 million items a year, this transaction acceleration triggers powerful value propositions to meet all market requirements.

Meet the new generation of 2025 consumer demands, and it’s never been more demanding with a tight, efficient supply chain. Companies that employ supply chain outsourcing can streamline logistics, improve the speed of delivery, and solidify reliability at all touchpoints. With outsourced supply chain management through to process improvement, every strategic development helps to create a better end-user experience.

Here’s how:

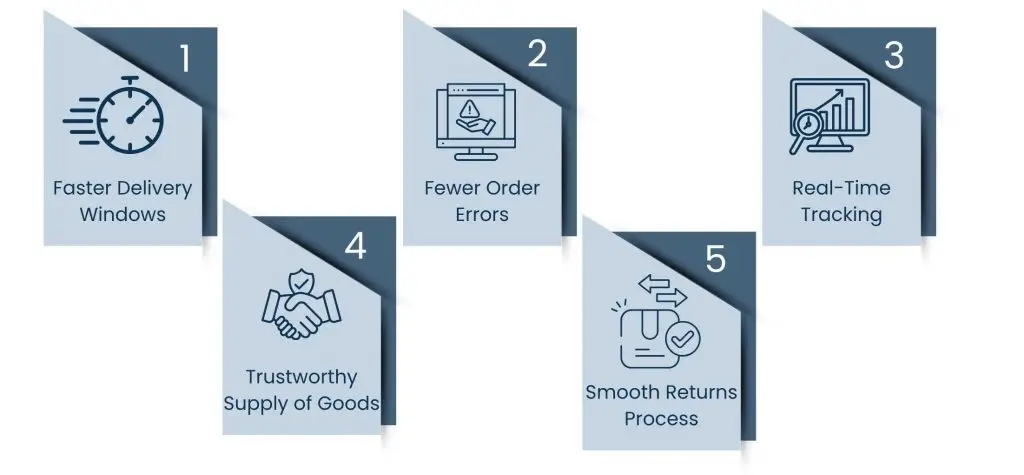

1. Faster Delivery Windows

With the use of third-party supply chain offerings, companies can access vast fulfillment networks and strategically placed warehouses. This cuts down the time it takes products to get to the customer and allows for same-day or next-day delivery in many areas. SCPIOs secure your delivery systems to be the fastest and most reliable. Quick delivery times result in happy customers, who in turn make frequent repeat purchases.

2. Fewer Order Errors

Manually processing orders can become costly if you’re making mistakes. With process betterment, outsourcing, automation, and precision are part of the process as they transition from picking, packing, tagging, to routing to get your product on its way to the consumer. This greatly decreases errors and increases overall fulfillment reliability. The result is a better user experience with fewer complaints and returns.

3. Real-Time Tracking

People demand to know where their orders are, and predictive supply chain outsourcing gives them just that. From our outsourced partners to our tracking systems, our customers can monitor their delivery from beginning to end and receive live updates. This is a testament to this transparency, the fact that customers ask for less support, and the buying experience gets better. It also optimizes control for companies with high throughput.

4. Trustworthy Supply of Goods

Subcontracting inventory management to outsource supply chain management aids in maintaining the highest possible level of stock by predictive demand. This decreases the risk of stockouts and overstock. In addition, by optimizing the supply chain through sourcing needs and by outsourcing supply chain optimization, companies can always make sure the right product is in the right place at the right time.

5. Smooth Returns Process

Return can be defined as the process of making sure returned products in the customer’s custody are accepted hassle-free within a return time frame. Outsourced vendor and supplier management and reverse logistics specialists streamline the management of returns by displaying easy-to-follow, automated instructions for the customer to return their goods. Delegated supply chain Solutions to manage returns quickly and provide a swift refund or exchange, to keep their business customers happy. A frictionless returns experience can be what makes the difference between a one-time purchaser and a long-term customer.

These improvements have the customer onboarding process faster, more seamless, and trustworthy, allowing operational effectiveness to become brand loyalty and business growth.

When to Consider Supply Chain Optimization Outsourcing?

Knowing the right time to adopt supply chain outsourcing can be a milestone for any company. Whether you’re hitting bottlenecks or going through hyper-growth, falling back on outsourcing will grant you access to faster fulfillment, better performance, and cost savings.

Chain management provides versatile methods to solve operational challenges and satisfy customers.

Here are signs it’s time to outsource:

1. Your Current Supply Chain Can No Longer Meet Customer Demand

Late deliveries, backorders, or missed SLAs are clear signs that your in-house resources are not keeping up. Many industries are stuck in the dark ages when it comes to technology and processes, but the right outsourced supply chain management partner can do wonders by bringing in efficiency-focused systems and teams. Tapping into third-party expertise via supply chain services means that goods can be fulfilled quickly even when demand is high. This change makes it more likely that customers will stay with and trust you.

2. You’re Branching Out to New Markets or Regions

Expanding into new markets presents both opportunities and logistical challenges, especially when you grow into new ventures. Supply chain outsourcing lets companies grow without the burden of infrastructure investment by leveraging partners with ready-made distribution. Supply chain performance improvement outsourcing secures standardized service levels around regions. This allows you to expand faster and with more focus on the customer.

3. Shipping Delays and Inventory Errors Are Piling Up

Common errors in orders, lost deliveries, or under- or over-stocking may affect client relationships and lead to losses. With process improvement, these challenges can be diagnosed and addressed with technology-enabled processes and actionable, real-time data. By adding predictive supply chain outsourcing to that, another layer of intelligence is added for the risks that impact performance.”

4. In-House Fulfillment Has Grown Too Costly or Complicated

Self-managing logistics, labor, and warehousing can become surprisingly cost and operationally-intensive. Businesses with third-party supply chain services are turning fixed costs into variable ones. An optimized supply chain outsourcing simplifies fulfillment and frees your internal staff to concentrate on strategic growth.

5. You Don’t Have the Tools to Track and Project Performance

If you’re still using spreadsheets or antiquated systems, you’re not seeing some valuable insights. Performance Improvement Outsourcing (SCPI-O) delivers KPIs, dashboards, and advanced analytics. Through predictive supply chain outsourcing, you can proactively make decisions on inventory, delivery routes, and supplier management, so there are fewer surprises and a lot less guesswork.

When you know the signs to look for, you can make more strategic decisions and outcompete your competition with better, quicker, and more agile supply chain operations.

Conclusion

Supply chain outsourcing is no longer simply a cost-saving option—it’s an action that can be taken for the benefit of long-term growth and customer service. With the help of outsourced supply chain management, businesses can optimise operations, eliminate delays, and ensure timely delivery to their customers.

When you’re growing into new markets, managing fulfillment roadblocks, and seeking to refine the way you do business, third-party supply chain services provide the flexibility and expertise to stay nimble. Outsourcing services allow businesses to make intelligent, data-based decisions that increase speed and efficiency.

Businesses no longer need to gamble; with automation, visibility, and analytics, all provide businesses with automated, real-time, perfect information on performance. Instead, they will be able to concentrate on growth, innovation, and customer engagement, and on the back end, have flawless supply chain operations.

Finally, supply chain performance and the improvement process enable companies to remain flexible in a competitive environment. The selection of the right partner for your process improvement supply chain outsourcing is paramount. With

Partner with Tasks Expert to streamline your supply chain, cut costs, and scale operations with greater speed and precision.

About Us

Tasks Expert offers top-tier virtual assistant services from highly skilled professionals based in India. Our VAs handle a wide range of tasks, from part time personal assistant to specialized services like remote it support services, professional bookkeeping service etc. Furthermore, it helps businesses worldwide streamline operations and boost productivity.

Ready to elevate your business? Book a Call and let Tasks Expert take care of the rest.